| Oil Pumps (Manual Gearbox Models) |

| Small Bore Engines (848, 997, 998 and 1098cc) |

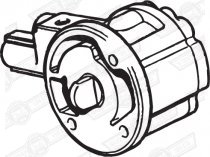

| Oil pumps on small bore A Series engines were manufactured by three different companies and were driven by two different couplings from the camshaft. The first manufacturer, Burman, produced a four vane, pin driven pump which saw use on the fist Minis built between 1959 and 1961. This pump went out of production soon after it ceased to be fitted on the production line and may be replaced by either of the other two companies' pumps, so long as the three original fixing screws and washer are also replaced by the later, longer bolts and lock tab. |

| |

|

|

|

|

| From 1961 the oil pump was changed to a rotor and annulus type, still driven by a pin in the end of the camshaft. It was dual-sourced from either Hobourn-Eaton or Concentric. While there are differences between the two manufacturers' products, they will directly replace each other, using the same bolts and lock tab to fix them to the cylinder block. |

| |

|

|

|

|

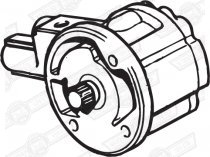

| The last change occurred towards the end of 1980, when the A Plus camshaft was introduced. This camshaft design had a slot in the oil pump driving end into which the oil pump shaft located, replacing the previous pin drive. The oil pump was still dual-sourced from the same manufacturers and because the pump to block fixing method is the same, Hobourn-Eaton and Concentric pumps will, as with the earlier pin drive types, directly replace each other. |

| |

|

|

|

|

| Big Bore Engines (970, 1071 and 1275cc) |

| The big bore engine oil pumps were sourced from two manufacturers, Hobourn-Eaton or Concentric. Cooper S engines from 1963-69 had a pin drive pump fixed by the same three bolts used on the the small bore engine pumps made by the same companies. However, upon the change to star drive oil pumps and camshafts in 1969, the Hobourn-Eaton pump became two bolt fixing and the Concentric pump became four bolt fixing. This situation continued after 1980 when the oil pump drive changed again to the A Plus slot drive type. |

| |

|

|

|

|

| Two and four bolt pumps are interchangeable, so long as the correct drive method is observed and the correct quantities of bolts are used. The flanged bolts fixing the oil pumps on 1990s Mini 1275cc engines (and Metro engines from 1984) may be used to fix any earlier star drive or slot drive 1275cc engine oil pump, replacing the original bolts and washers or lock tabs. |

| |

|

|

|

|

| Oil Pump Interchangeability |

| Some standard profile and particularly uprated camshafts are increasingly only available in slot drive format, which means if you have an earlier engine you may well have to change your oil pump from pin or star drive to a slot drive type; there is no problem in doing so, so long as the correct fixings are also used. |

| |

|

|

|

|

| It used to be the case, back in the 1960s, that if you wanted a high capacity oil pump you would fit the Cooper S item (note that high capacity does not mean high pressure; it simply means that more oil is pumped around the engine - oil pressure is of course controlled by the oil pressure relief valve). However from 1968 all oil pumps excluding that fitted to the MG Metro Turbo and ERA Mini Turbo, but including replacements for the earlier 1960s types, have been of Cooper S capacity. As a result, if you want a high capacity oil pump today, you can fit the GLP110 Metro/Mini Turbo item. |

| |

|

|

|

|

| For those who mix and match their engine components, it is possible to fit a big bore engine oil pump in a small bore engine - for example, the Metro Turbo pump. Firstly, the oil pump drive from the camshaft must be correct, which means in the case of the Turbo pump you will need a slot drive camshaft in your engine. Secondly, star drive and slot drive big bore engine oil pumps are two or four bolt fixing, whereas small bore engine oil pumps use three bolts. Some of the oil pumps supplied today have five bolt holes, which means they can be fitted with either two, three or four bolts, as appropriate. If however your pump has only two or four bolt holes, you will need to drill and tap a small bore cylinder block with sufficient holes to accept the pump. |

| |

|

|

|

|

| A big bore Cooper S engine built before 1969 faces the same pump fixing problems if a non-standard star drive or slot drive camshaft is to be fitted. The original pin drive pump for this engine is three bolt fixing, so to fit a star drive or slot drive oil pump you will need to either ensure that you purchase a five bolt hole pump or drill and tap the cylinder block to accept a two or four bolt fixing. Post 1969 Cooper S engines are ready machined for two or four bolt fixings. |

| |

|

|

|

|

| Lastly, the oil pump in a big bore engine sits in a different position from its small bore equivalent, relative to the camshaft. This means that to fit a big bore engine pump in a small bore engine (for example, fitteing a star drive pump to allow use of a star drive cam), a 12G1127 spacer will be required. |

| |

|

|

|

|

| 848, 997, 998 and 1098cc 1959-80 |

| (pin drive from camshaft) |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 1 |

2A819 |

OIL PUMP ASSEMBLY, Burman |

1 |

848cc 1959-61. No longer serviced; use Hobourn-Eaton or Concentric pump with correct bolts and lock tab. |

| 2 |

SH604051 |

SCREW, oil pump to cylinder block |

3 |

848cc 1959-61. Burman pump only. |

| 3 |

LWZ304 |

WASHER, locking |

1 |

848cc 1959-61. Burman pump only. |

| 4 |

GLP142 |

OIL PUMP ASSEMBLY, Hobourn-Eaton or Concentric |

1 |

1961-80. |

| 5 |

BH604141 |

BOLT, oil pump to cylinder block |

3 |

1961-80. |

| 6 |

12G926 |

WASHER, tab |

1 |

1961-80. |

| 7 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| |

|

|

|

|

| 848, 998 and 1098cc A Plus 1980 On |

| (slot drive from camshaft) |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 8 |

GLP139 |

OIL PUMP ASSEMBLY, Hobourn-Eaton or Concentric |

1 |

|

| 9 |

BH604141 |

BOLT, oil pump to cylinder block |

3 |

|

| 10 |

12G926 |

WASHER, tab |

1 |

If fitted. |

| 11 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| |

|

|

|

|

| 970, 1071 and 1275cc Cooper S 1963-69 |

| (pin drive from camshaft) |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 12 |

AEG178 |

OIL PUMP ASSEMBLY, Hobourn-Eaton |

1 |

|

| |

AEG410 |

OIL PUMP ASSEMBLY, Concentric |

1 |

|

| 13 |

BH604141 |

BOLT, oil pump to cylinder block |

3 |

|

| 14 |

12G926 |

WASHER, tab |

1 |

|

| 15 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| |

|

|

|

|

| 1275cc Cooper S and 1275 GT 1969-80 |

| (star drive via 'spider' on camshaft) |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 16 |

GLP141 |

OIL PUMP ASSEMBLY, Hobourn-Eaton or Concentric |

1 |

|

| 17 |

BH604131 |

BOLT, oil pump to cylinder block |

2/4 |

Qty. 2 for Hobourn-Eaton pump, qty. 4 for Concentric pump. |

| 18 |

LWZ204 |

WASHER, locking |

2 |

For Hobourn-Eaton pump. |

| 19 |

12G2098 |

LOCK TAB, upper |

1 |

For Concentric pump. |

| 20 |

12G2097 |

LOCK TAB, lower |

1 |

For Concentric pump. |

| 21 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| 22 |

12G1127 |

SPACER, oil pump to cylinder block |

1 |

Allows fitment of 1275cc oil pump to 848, 998 or 1098cc block (see notes above). |

| |

|

|

|

|

| 1275cc A Plus 1980 On |

| (slot drive from camshaft) |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 23 |

GLP138 |

OIL PUMP ASSEMBLY, Hobourn-Eaton or Concentric |

1 |

Standard capacity. |

| |

GLP110 |

OIL PUMP ASSEMBLY, Hobourn-Eaton |

1 |

High capacity (MG Metro Turbo pump). |

| 24 |

BH604131 |

BOLT, oil pump to cylinder block |

2/4 |

1980. Qty. 2 for Hobourn-Eaton pump, qty. 4 for Concentric pump. |

| 25 |

LWZ204 |

WASHER, locking |

2/4 |

1980. Qty. 2 for Hobourn-Eaton pump, qty. 4 for Concentric pump. |

| 26 |

TAM1174 |

BOLT, oil pump to cylinder block |

2/4 |

1990 on. Qty. 2 for Hobourn-Eaton pump, qty. 4 for Concentric pump. |

| 27 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| 28 |

12G1127 |

SPACER, oil pump to cylinder block |

1 |

Allows fitment of 1275cc oil pump to 848, 998 or 1098cc block (see notes above). |

| |

|

|

|

|

| Oil Pumps (Automatic Gearbox Models) |

| Much easier to describe and list than their manual gearbox counterparts, there are in fact only two different types of oil pump on automatic Minis: the star drive type and the A Plus slot drive type. |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 29 |

GLP113 |

OIL PUMP ASSEMBLY, Hobourn-Eaton |

1 |

1964-80; star drive type. |

| 30 |

GLP107 |

OIL PUMP ASSEMBLY, Hobourn-Eaton |

1 |

1980 on; slot drive type (A Plus). |

| 31 |

12A1254 |

SCREW, cap, oil pump to cylinder block |

3 |

|

| 32 |

GUG705560GM |

GASKET, oil pump to cylinder block |

1 |

|

| 33 |

22A1185 |

PIPE ASSEMBLY, oil outlet |

1 |

|

| 34 |

22A1187 |

BLOCK, outlet pipe |

1 |

|

| 35 |

22A1560 |

O RING, pipe and block |

2 |

|

| 36 |

22A1562 |

O RING, pipe to block |

1 |

|

| |

|

|

|

|

| Oil Pressure Relief Valve |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 37 |

12H865 |

PLUNGER, oil pressure relief valve |

1 |

Standard fitment. |

| 38 |

BLS916 |

BALL, oil pressure relief valve |

1 |

Alternative; see note below. |

| The ball above may be used in place of the standard fitment plunger to guard against a sticking relief valve (something that the plunger is prone to do, given dirt or metal particles in the oil). It must, however, be used in conjunction with the shorter and stronger AEA536 spring. |

| |

|

|

|

|

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 39 |

6K853 |

SPRING, oil pressure relief valve |

1 |

Standard fitment. |

| 40 |

AEA536 |

SPRING, oil pressure relief valve |

1 |

Uprated fitment, plus 1961-71 Cooper models. |

| 41 |

12A1851 |

CAP, threaded, relief valve |

1 |

|

| 42 |

6K431 |

WASHER, sealing |

1 |

|

| 43 |

2A797 |

HOUSING, oil pressure relief valve |

1 |

Press-fit in cylinder block. |

| |

|

|

|

|

| Models fitted with an oil pressure gauge employ a metal pipe between an adaptor on the pressure switch tapping on the cylinder block and the hose running to the gauge itself: |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 44 |

CAM4202 |

PIPE ASSEMBLY, oil pressure |

1 |

|

| 45 |

ACA5419 |

OLIVE, union |

1 |

Included in pipe assembly. |

| 46 |

ACA5422 |

NIPPLE, union |

1 |

Included in pipe assembly. |

| 47 |

ACA5421 |

NUT, union |

1 |

Included in pipe assembly. |

| 48 |

PCR211 |

CLIP, pipe securing |

1 |

|

| 49 |

2A269 |

ADAPTOR, oil pressure pipe to cylinder block |

1 |

Original fitment. |

| |

OA |

ADAPTOR, oil pressure pipe to cylinder block |

1 |

Alternative fitment. |

| |

|

|

|

|

| To enable operation of both an oil pressure gauge and oil pressure light, a tee piece may be screwed in to the cylinder block, accepting both the pressure pipe adaptor and pressure warning light switch: |

| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| 50 |

TP |

TEE PIECE, oil pressure pipe and switch to block |

1 |

|

| 51 |

2K4956 |

WASHER, fibre |

1 |

|