| Ill. No. |

Part No. |

Description |

Qty. Rqd. |

Remarks |

| |

|

|

|

|

| Bodyshells |

|

|

|

| If you are faced with repairing a severely corroded or accident damaged Mini, opting instead for a new British Motor Heritage bodyshell would be a wise move indeed. A new bodyshell compares very favourably in cost against a heavy rebuild of your old bodyshell, and at the end of the job provides the degree of build integrity that old, repaired bodies simply cannot match. Nowhere is this statement more relevant than when the subject is the Mini Clubman bodyshell. Because the extra space in the engine bay allowed the fitment of more extreme power plants, Mini Clubmans were always (still are) favourite candidates for custom and high performance special builds. A taut, fatigue-free new bodyshell allows for safer enjoyment of uprated power, suspension and braking packages. |

| |

|

|

|

|

| British Motor Heritage Mini bodyshells are supplied in two conditions of build: Body Complete Assembly, fitted with doors, bonnet and boot lid, or Body Less Doors, which as the name suggests are supplied less the ‘closure’ panels and associated hinges. The panels, pressed in the original equipment dies, are then assembled by original processes on the jigs and fixtures used by Rover Group and its predecessors. |

| |

|

|

|

|

| The completed bodyshells are usually electrophoretically coated, seam sealed and then primed with water-bourne paint to the latest industry standards, ready for your colour coat application. Occasionally, for manufacturing reasons, BMH may vary the finishing specifications; please contact us before placing your bodyshell order to establish whether there are any changes that you should be aware of. |

| |

|

|

|

|

| Because of the many detail changes made on an annual - if not more frequent, sometimes - basis while the Mini was in production, it is strongly advised that you carry out ‘dry run’ test fitments of as many parts as you can prior to top coat painting the bodyshell. By doing this, you can make any adjustments that are necessary to the bodyshell without the frustration of damaging new paintwork. |

| |

|

|

|

|

| Also ensure that all captive and weld nut threads on the bodyshell are cleared of paint after the top coat has been applied - in fact, make it the first job before starting to fit out the bodyshell. This will avoid the other great frustrations of sheared screws and captive nuts that have broken free when too much force has been used to get the screw threads to cut through the paint! Clearing the threads can be easily achieved with a set of imperial UNF threadform taps (plus a couple of metric ones for later models), but do go gently otherwise the tap will strip the thread you’re trying to clear. |

| |

|

|

|

|

| The following are the specifications of bodyshell available at time of writing. |

|

|

| |

|

|

|

|

| Clubman Saloon Bodyshells (1976 on) |

|

|

| These bodyshells are most suitable for models built from 1976 onwards. They may also be used for some earlier models built between 1969 and 1975, if the later rubber mounted front subframe is utilised; please phone for details. While they are as close as reasonably possible to original specification, for commercial reasons these bodyshells are built with a handful of later specification components, which may require slight adjustments to be made for fitting out. |

| |

CZH594 |

BODY COMPLETE ASSEMBLY |

1 |

For Clubman and 1275GT saloons. |

| 1 |

CZH588 |

BODY LESS DOORS ASSEMBLY |

1 |

For Clubman and 1275GT saloons. |

| |

|

|

|

|

| Front End Assembly |

|

|

|

| 2 |

CZH3190 |

FRONT END ASSEMBLY |

1 |

1969-75; solid subframe mounts (MkIII). |

| |

CZH3223 |

FRONT END ASSEMBLY |

1 |

1976-82; rubber subframe mounts (MkIV). |

| CZH3190 includes a depression in the dash crossmember giving clearance for waxstat carburetters; the crossmember is therefore visually different from that in early models. The toeboard is designed for rod change gearboxes and may need some alteration for use on very early models with a remote gear change. |

| For details of the dash included in a front end assembly, please refer to the Dash Assembly section. |

| 3 |

21A471 |

BRACKET ASSY., front shock absorber, RH |

1 |

Not Hydrolastic suspension models. |

| |

21A474 |

BRACKET ASSY., front shock absorber, LH |

1 |

Not hydrolastic suspension models. |

| 4 |

SH604051 |

SCREW, bracket attaching |

8 |

|

| 5 |

LWZ204 |

WASHER, locking |

8 |

|

| |

|

|

|

|

| Front Wings, Front Panel and Bonnet |

|

|

| 6 |

CZH408 |

FRONT WING, RH |

1 |

|

| |

CZH408P |

FRONT WING, RH |

1 |

Non-genuine. |

| 7 |

CZH409 |

FRONT WING, LH |

1 |

|

| |

CZH409P |

FRONT WING, LH |

1 |

Non-genuine. |

| 8 |

14A7602 |

SUPPORT ANGLE, wing to A panel |

2 |

|

| 9 |

HMP441039 |

GRILLE COMPLETE ASSEMBLY |

1 |

1969-75; solid subframe mountings. |

| |

HMP441040 |

GRILLE COMPLETE ASSEMBLY |

1 |

1976 on; rubber subframe mountings. |

| 10 |

CZH120 |

MOUNTING PANEL, headlamp, RH |

1 |

|

| 11 |

CZH121 |

MOUNTING PANEL, headlamp, LH |

1 |

|

| 12 |

CZH149 |

BONNET LOCKING PLATFORM |

1 |

|

| |

CZH149P |

BONNET LOCKING PLATFORM |

1 |

Non-genuine. |

| 13 |

CZH155 |

SUPPORT, bonnet locking platform |

1 |

|

| 14 |

CZH563 |

FRONT VALANCE ASSEMBLY |

1 |

1969-75; solid subframe mountings. |

| |

AAM1022 |

FRONT VALANCE ASSEMBLY |

1 |

1976 on; rubber subframe mountings. |

| |

AAM1022P |

FRONT VALANCE ASSEMBLY |

1 |

1976 on; non-genuine. |

| 15 |

CZH520 |

BONNET ASSEMBLY |

1 |

1969-70; fits to hinges with screws. |

| |

CZH2609 |

BONNET ASSEMBLY |

1 |

1970 on; fits to hinges with nuts. |

| 16 |

SH604051 |

SCREW, hinge to bonnet |

4 |

1969-70. |

| 17 |

PWZ104 |

WASHER, plain |

8 |

1969-70. |

| 18 |

LWZ204 |

WASHER, locking |

4 |

1969-70. |

| 19 |

NH604041 |

NUT, hinge to bonnet |

4 |

1970 on. |

| 20 |

LWZ204 |

WASHER, locking |

4 |

1970 on. |

| 21 |

PWZ104 |

WASHER, plain |

4 |

1970 on. |

| 22 |

CZH200 |

ROD, bonnet prop |

1 |

|

| 23 |

24A859 |

CLIP, prop rod |

1 |

|

| 24 |

14A366 |

SAFETY CATCH ASSEMBLY |

1 |

|

| |

|

|

|

|

| Inner Wings |

|

|

|

| An inner wing complete assembly includes inner wing, A panel, gusset and front pillar stiffener. |

| 25 |

CZH410 |

INNER WING COMPLETE ASSEMBLY, RH |

1 |

|

| 26 |

CZH414 |

INNER WING ASSY., without A panel, RH |

1 |

|

| 27 |

CZH3062 |

INNER WING REPAIR, front half, RH |

1 |

|

| 28 |

REPAN068 |

INNER WING REPAIR, rear, full height, RH |

1 |

Non-genuine. |

| 29 |

REPAN029 |

INNER WING REPAIR, rear lower, RH |

1 |

Non-genuine. |

| 30 |

ALA5660 |

A PANEL, RH |

1 |

|

| |

ALA5660P |

A PANEL, RH |

1 |

Non-genuine. |

| 31 |

14A8348 |

GUSSET, A panel to inner wing, RH |

1 |

|

| 32 |

ALA6472 |

STIFFENER ASSEMBLY, front pillar, RH |

1 |

|

| 33 |

CZH567 |

INNER WING COMPLETE ASSEMBLY, LH |

1 |

|

| 34 |

CZH569 |

INNER WING ASSY., without A panel, LH |

1 |

|

| 35 |

CZH3063 |

INNER WING REPAIR, front half, LH |

1 |

|

| 36 |

REPAN069 |

INNER WING REPAIR, rear, full height, LH |

1 |

Non-genuine. |

| 37 |

REPAN030 |

INNER WING REPAIR, rear lower, LH |

1 |

Non-genuine. |

| 38 |

ALA5661 |

A PANEL, LH |

1 |

|

| |

ALA5661P |

A PANEL, LH |

1 |

Non-genuine. |

| 39 |

14A8349 |

GUSSET, A panel to inner wing, LH |

1 |

|

| 40 |

ALA6473 |

STIFFENER ASSEMBLY, front pillar, LH |

1 |

|

| 41 |

CZH570 |

COWLING ASSEMBLY, radiator |

1 |

|

| The gussets 14A8348 and 14A8349 also serve the purpose of closing the space under the lower corners of the windscreen frame. They’re fitted to all Minis, not just Clubmans, and are contenders for the title of most rust-prone panels on the car. Whenever you remove a wing, have a look under the windscreen lower corner while you can easily get access to it, and check the condition of the gusset (if it’s still there at all). It’s a very good idea to replace it while you can get to it, rather than waiting for the telltale leak to start behind the corner of the dashboard. |

| |

|

|

|

|

| Windscreen |

|

|

|

| 42 |

CZH3140 |

WINDSCREEN COMPLETE ASSEMBLY |

1 |

Includes header rail and boxing plates. |

| 43 |

HMP441001 |

WINDSCREEN REPAIR, lower, full width |

1 |

|

| 44 |

REPAN033 |

WINDSCREEN REPAIR, lower corner, RH |

1 |

Non-genuine. |

| 45 |

REPAN034 |

WINDSCREEN REPAIR, lower corner, LH |

1 |

Non-genuine. |

| 46 |

ALA5790 |

HEADER RAIL ASSEMBLY |

1 |

|

| 47 |

14A8015 |

TAPPED PLATE, interior mirror |

1 |

Included in header rail assembly. |

| 48 |

ALA5696 |

BOXING PLATE, windscreen pillar, RH |

1 |

|

| 49 |

ALA5697 |

BOXING PLATE, windscreen pillar, LH |

1 |

|

| |

|

|

|

|

| Body Shop Consumables |

|

|

| Somerford Mini is proud to be able to offer the Dinitrol range to protect your cherished Mini from the dreaded rust threat. Acclaimed as ‘Best in Test’ by Practical Classics magazine, Dinitrol 3125 cavity wax and 4941 underbody wax are used by the UK armed forces and protect their vehicles (with intact underbody paint) in up to 1.5 metres of salt water! |

| The Dinitrol Complete Rust-Proofing Kit includes a 500ml can of Rust Converter, two 1 litre cans of 3125 Cavity Wax, three 1 litre cans of 4941 Underbody Wax, the Professional Wax Injection Kit, a 10mm drill and a car set of 10mm body plugs - everything you need to give your Mini theultimate rust protection. |

| 50 |

WC001 |

RUST CONVERTER, ‘Dinitrol’ |

A/R |

1 litre can. |

| 51 |

WC002 |

CAVITY WAX, ‘Dinitrol 3125 Corromax’ |

A/R |

1 litre can. |

| 52 |

WC003 |

RUST PROOFING KIT, ‘Dinitrol’ |

A/R |

|

| 53 |

WC004 |

UNBERBODY WAX, ‘Dinitrol 4941’ |

A/R |

1 litre can. |

| 54 |

WC005 |

‘SMOOTHRITE’ PAINT, brush-on, black |

A/R |

500ml can. |

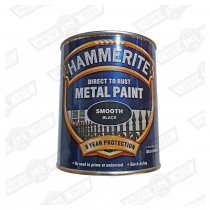

| 55 |

WC006 |

‘HAMMERITE’ PAINT, brush-on, black |

A/R |

500ml can. |

| 56 |

WC007 |

SEAM SEALANT, brush-on |

A/R |

1 kg can. |

| 57 |

WC013 |

SEAM SEALANT, polyurethane |

A/R |

300ml cartridge. |

| 58 |

WC008 |

ZINC-RICH SEALANT, weld-through |

A/R |

400ml aerosol. |

| 59 |

WC009 |

WINDSCREEN SEALANT |

A/R |

300ml cartridge. |

| |

|

|

|

|

| We also stock bright mild steel sheet for localised repair use. Sold by the square foot, it is available in 18SWG and 20SWG thicknesses: |

| 60 |

STEEL18SWG |

STEEL SHEET, 18SWG |

A/R |

Sold per square foot. |

| 61 |

STEEL20SWG |

STEEL SHEET, 20SWG |

A/R |

Sold per square foot. |